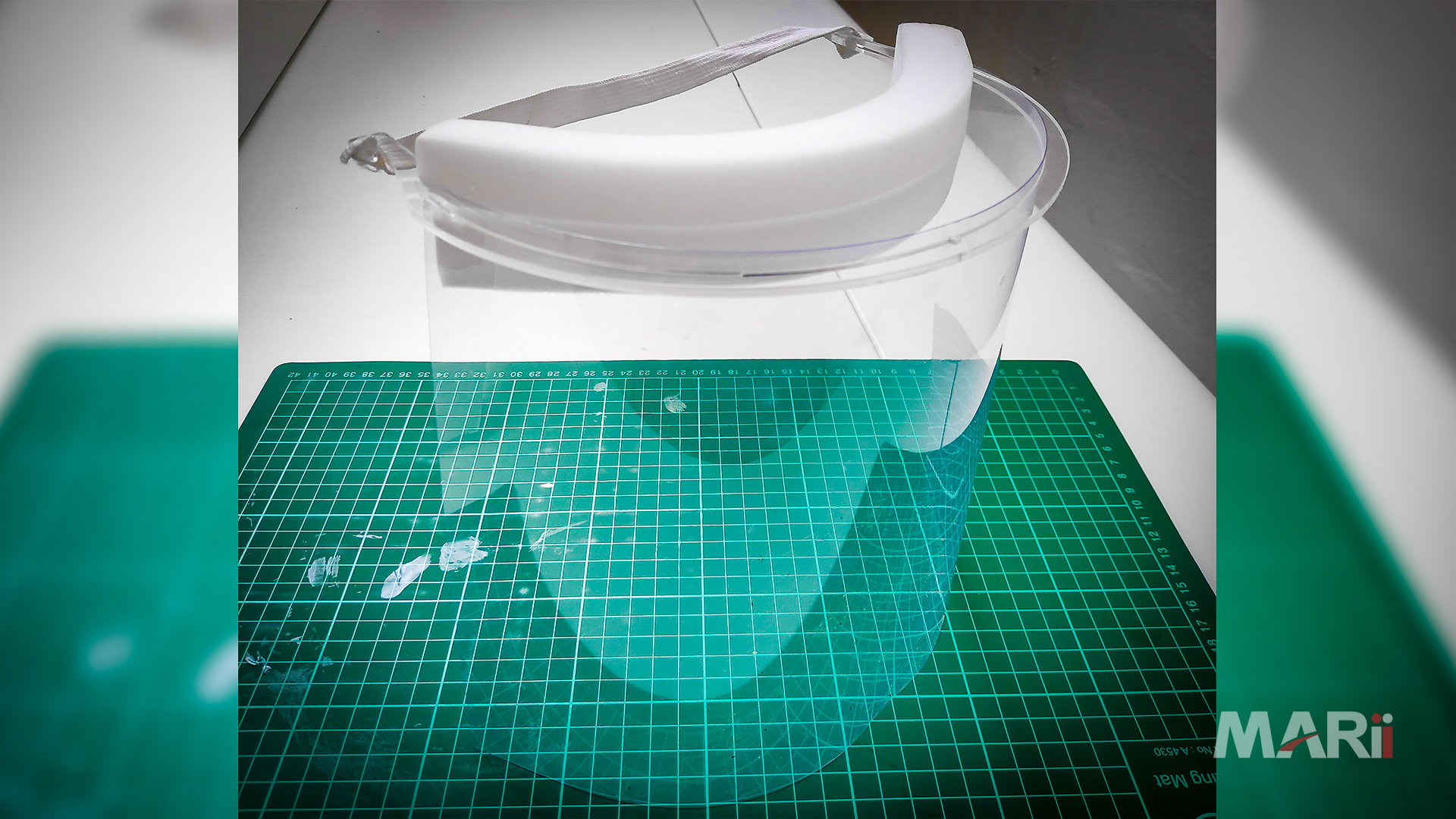

Cyberjaya – The Malaysia Automotive, Robotics and IoT Institute (MARii), together with a local tech company will start production of personal protective equipment (PPE), namely face shields and intubation boxes for the use medical workforce in their efforts to curb the spreading of the COVID-19 pandemic.

The PPE items will be produced using the laser cutting process, a process to cut, weld and mark plastic through the application of pinpoint, accurate application of heat to plastic sheets to the desired shape. A laser beam is guided by the machine through a path based on the design performed by CAD software.

The process allows for faster and efficient production without the need for additional tooling, and can use easily sourced materials (given the restrictions placed on the export/import sector) such as acrylic and Perspex.

“In order to ensure that PPE is readily-available despite shutdown of many manufacturers and raw material limitations, the deployment of technologies to rapidly manufacture PPE are crucial. MARii’s technology network has opened up opportunities for quick action to be taken for the PPE supply issue, and we hope more solutions can be developed to address other issues surrounding the pandemic”, said Dato’ Madani Sahari, CEO of MARii.

The usage of laser cutting machines requires minimal operational supervision, reducing the risks of virus transmission through a simpler process workflow.

It also allows for instant redesign and modification of products to suit specific needs, therefore saving ample time through the elimination of tooling modification that is common in injection moulding.

Dato’ Madani also explained that about 1000 face shields and 50 intubation boxes can be produced per day.

“These benefits make laser cutting a highly viable process in situations such as COVID-19, where single use products face a huge spike in demand”, he added.

Leave a comment